Understanding Model Manufacturing in Architecture

In the world of architecture, model manufacturing plays a crucial role in translating abstract concepts into tangible representations. Models serve not merely as tools for visualization but also as critical components of the design process. This article delves deeply into the various aspects of model manufacturing, exploring its importance for architects, different types of models, the processes involved, and the latest advancements in technology that are shaping this field.

The Importance of Model Manufacturing for Architects

For architects, the ability to present ideas clearly and effectively is paramount. Model manufacturing provides a concrete visual representation of projects that can significantly enhance communication with clients, stakeholders, and regulatory bodies. Here are some reasons why model manufacturing is essential:

- Enhanced Communication: Models facilitate better understanding among non-technical stakeholders, allowing them to visualize the proposal more accurately.

- Design Iteration: Physical models enable architects to experiment with form, scale, and materials before finalizing designs.

- Marketing Tools: High-quality models serve as persuasive marketing materials that can capture the attention of potential clients and investors.

- Problem Identification: Building a model can highlight potential design flaws early in the process, allowing for timely adjustments.

- Collaboration: Working with models fosters collaborative discussions among team members, leading to innovative solutions.

Types of Models in Model Manufacturing

Model manufacturing encompasses various types of models, each serving a unique purpose within the architectural design process. The primary types include:

1. Conceptual Models

Conceptual models are often created during the initial stages of design. They help architects visualize their ideas without going into intricate detail, focusing instead on proportions, scale, and overall form.

2. Presentation Models

These models are crafted for the purpose of presenting the design to clients or stakeholders. They are usually highly detailed and finished, providing an attractive representation of how the final project will appear.

3. Working Models

Working models are more functional, often used to test design concepts. They may incorporate movable parts or simulate operations, giving insight into functionality and user experience.

4. Terrain Models

Terrain models are vital for understanding how a building will interact with its environment. These can include landscape features, topography, and significant surrounding structures.

5. Virtual Models

With advancements in technology, virtual models using CAD and 3D rendering software have become prominent. These digital models allow for real-time modifications and can be shared easily across different platforms.

Processes Involved in Model Manufacturing

The journey of model manufacturing typically encompasses several key stages, which include:

1. Conceptualization

During this phase, architects brainstorm ideas and sketch out rough concepts. The goal is to generate an initial understanding of the design.

2. Design Development

Here, the selected concept is refined. Architects create digital drafts and simulations, using tools like CAD software to fine-tune dimensions, materials, and aesthetics.

3. Prototyping

Prototyping involves creating preliminary physical models based on the refined designs. This helps identify any major flaws or necessary adjustments before proceeding to final models.

4. Final Model Creation

The final model is crafted with careful attention to detail. The choice of materials, finishes, and techniques is critical to ensure that the model meets the goals of presentation and functionality.

5. Testing and Evaluation

Finally, models are tested for structural integrity and practicality. It’s essential to gauge how well the model represents the design intention and whether it effectively communicates the architectural concept.

Advancements in Model Manufacturing Technology

Technology has significantly transformed the field of model manufacturing, introducing tools and techniques that enhance productivity and creativity. Some notable advancements include:

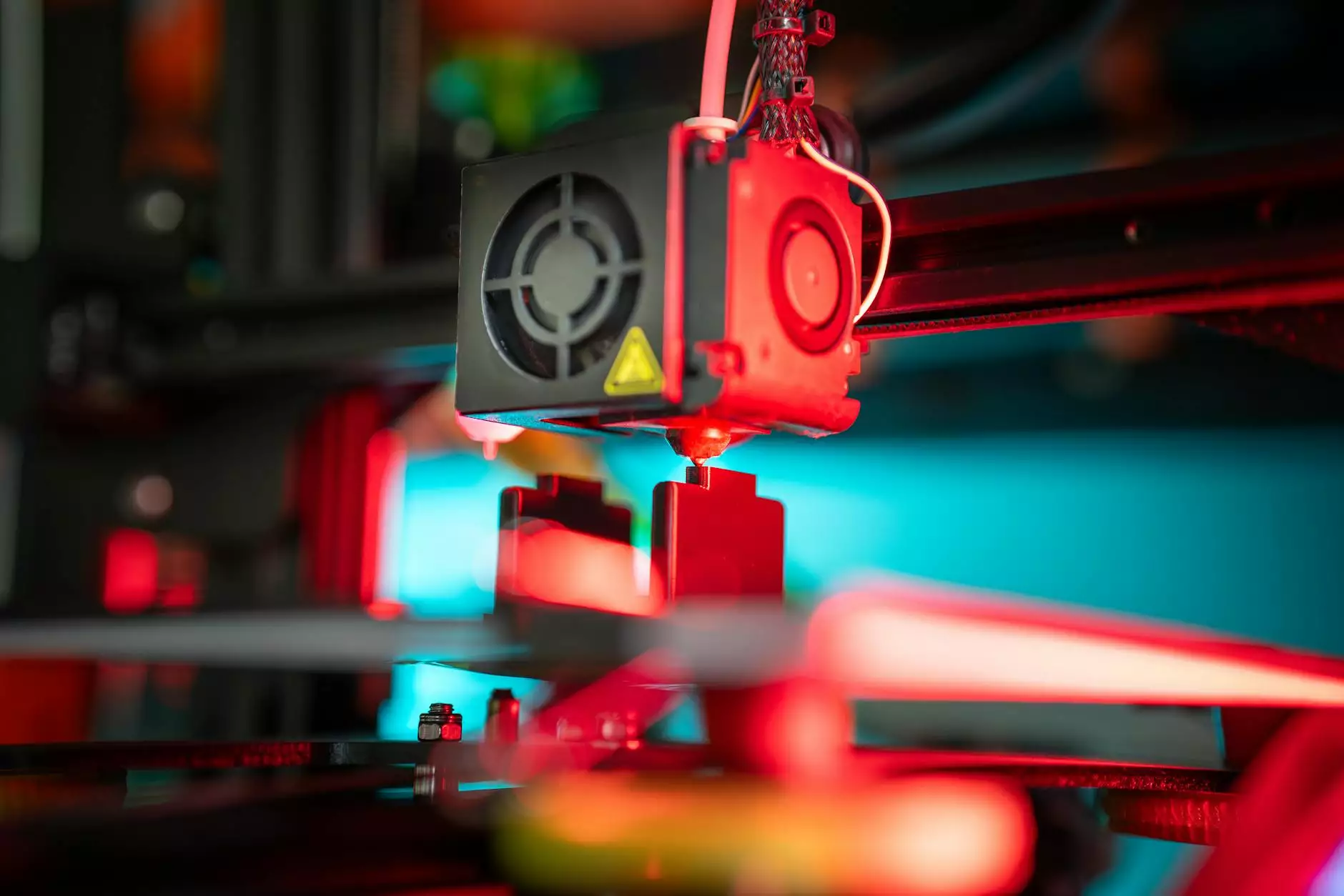

1. 3D Printing

3D printing has revolutionized model creation. Architects can produce highly complex and detailed models in a fraction of the time it would take to craft them by hand. This technology allows for rapid prototyping and iteration.

2. Digital Fabrication

Techniques such as CNC (Computer Numerical Control) milling and laser cutting have improved precision in model manufacturing. These methods ensure that components fit together perfectly, enhancing the overall quality of the final model.

3. Virtual Reality (VR) and Augmented Reality (AR)

With VR and AR, architects can present their designs in immersive environments. This engages clients in ways that traditional models cannot, allowing them to experience designs before they are built.

4. Sustainable Materials

Eco-friendly materials are becoming increasingly important in model manufacturing. With a growing emphasis on sustainability, many architects are turning to biodegradable and recycled materials for their models.

Choosing the Right Model Manufacturing Partner

For architects looking to outsource model manufacturing, selecting the right partner is vital. Here are some considerations:

- Experience: Look for a company with a proven track record in architectural model making.

- Portfolio: Review their previous work to ensure they align with your design vision.

- Technology: Ensure they utilize the latest technologies and materials in their manufacturing process.

- Communication: Clear communication is essential for successful collaboration. A good partner should prioritize transparency.

- Customization: Each project is unique, and your partner should offer tailored solutions that fit your specific needs.

The Future of Model Manufacturing in Architecture

As technology continues to evolve, the future of model manufacturing looks promising. Architects can expect to see increased integration of AI and machine learning to optimize design processes, further advancements in sustainable materials, and even more immersive technologies that enhance client engagement.

Overall, model manufacturing is an indispensable aspect of architecture that bridges the gap between concept and reality. By leveraging high-quality models, architects can improve their design processes, enhance communication, and ultimately bring their visions to life in ways that resonate with clients and communities alike.

Conclusion

In conclusion, model manufacturing serves as a cornerstone in the architectural profession. Whether for conceptualization, presentation, or functional testing, models play a vital role in ensuring that architectural projects are viable and compelling. As trends and technologies evolve, architects who embrace these changes will find themselves well-positioned to meet the challenges of an increasingly competitive market.

Exploring and investing in model manufacturing is not just an enhancement; it is becoming a necessity in the field of architecture. By prioritizing this aspect of their work, architects can elevate their projects and solidify their place in an industry that values innovation and excellence.