What Is a Ferrule Fitting?

Ferrule fittings are an integral component in the realm of fluid transfer and piping systems. They play a critical role in connecting pipes and tubes, ensuring leak-proof seals and facilitating efficient fluid flow. Understanding what ferrule fittings are, how they function, and their applications is crucial for anyone involved in the piping, plumbing, or fluid transport industries.

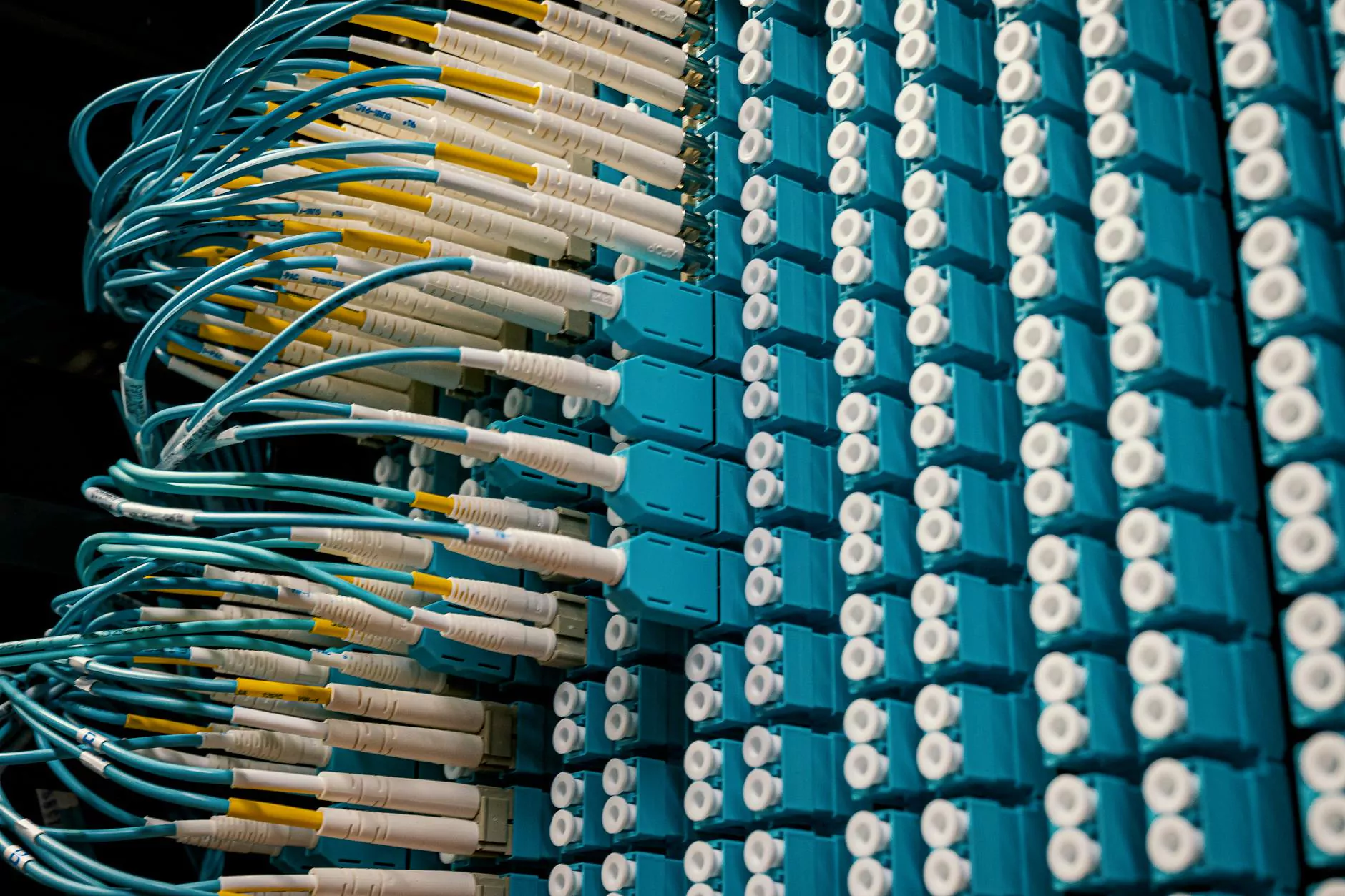

The Basics of Ferrule Fittings

A ferrule fitting is typically comprised of three main components: a body, a ferrule, and a nut. The ferrule, often made from materials such as brass or stainless steel, is designed to grip the tube or pipe tightly when the nut is tightened. This design creates a strong connection that can withstand significant pressure and temperature variations.

Why Use Ferrule Fittings?

The use of ferrule fittings offers several advantages:

- Leak Resistance: Ferrule fittings provide an excellent seal, preventing leaks that can be detrimental to operational efficiency.

- Versatility: They can be used in a variety of applications and environments, including high-pressure and high-temperature systems.

- Easy Installation: Ferrule fittings are relatively easy to install and require minimal maintenance, making them user-friendly.

- Durability: Often constructed from high-quality materials, they boast a long service life, reducing the need for frequent replacements.

Types of Ferrule Fittings

Ferrule fittings come in various designs, each tailored for specific applications and needs. Here are some of the most common types:

1. Double Ferrule Tube Fittings

Double ferrule fittings consist of two ferrules, which provide enhanced sealing capabilities. This type is particularly favored in high-pressure systems as it minimizes the risk of leakage and accommodates thermal expansion better than single ferrule fittings.

2. Single Ferrule Tube Fittings

Single ferrule fittings feature one ferrule that grips the tube against the fitting body. They are simpler in design and are suitable for less demanding applications, though they still offer reliable performance.

3. NPT Fittings

National Pipe Tapered (NPT) fittings utilize tapered threads to create a tight seal when screwed together. Ferrule designs can be integrated into NPT fittings to enhance their sealing capability, especially in high-pressure scenarios.

Applications of Ferrule Fittings

The applications of ferrule fittings are extensive and span multiple industries, including:

- Oil and Gas: Used in subsea applications and offshore platforms where robust sealing is critical.

- Chemical Processing: Ideal for systems handling aggressive chemicals due to their corrosion-resistant materials.

- Pharmaceuticals: Utilized in sanitary applications where leak-proof connections are essential to maintain product integrity.

- Automotive: Ferrule fittings are commonly found in hydraulic systems where reliability and performance are paramount.

- Aerospace: Leveraged in critical applications where performance under extreme conditions is necessary.

Why Choose High-Quality Ferrule Fittings?

When selecting ferrule fittings, the quality can significantly impact system performance and safety. High-quality ferrule fittings reduce the susceptibility to wear, corrosion, and fatigue, ultimately enhancing the longevity and reliability of your systems. At Techtubes.in, we prioritize offering top-grade ferrule fittings tailored to meet diverse industry standards.

Factors to Consider When Choosing Ferrule Fittings

When choosing the right ferrule fittings for your application, consider these factors:

- Material: The choice of material (e.g., stainless steel, brass) affects corrosion resistance and strength.

- Pressure Rating: Ensure the fitting can withstand the pressure levels that will be present in your application.

- Temperature Range: Fittings must be selected based on the operating temperature of the system.

- Compatibility: Ensure the ferrule fitting is compatible with the tubes or pipes you are using.

Maintenance Tips for Ferrule Fittings

Proper maintenance of ferrule fittings is essential to ensure optimal performance. Here are some tips:

- Regular Inspections: Inspect fittings for signs of wear, corrosion, or damage regularly.

- Proper Tightening: Ensure fittings are installed and tightened according to the manufacturer's specifications to avoid leakage.

- Cleanliness: Keep the area around the fittings clean to prevent contaminants from entering the system.

- Replacement: Replace fittings that show any signs of degradation, as this can lead to system failures.

The Future of Ferrule Fittings

As industries continuously evolve, the demand for more efficient and durable ferrule fittings is growing. Innovations in manufacturing processes, such as advanced materials and precision engineering, are paving the way for next-generation ferrule fittings that can withstand even more extreme conditions.

Technological Advancements

With the rise of technologies like 3D printing and smart materials, future ferrule fittings may offer enhanced monitoring capabilities and maintenance alerts. These advancements can significantly improve operational efficiency and reduce downtime in critical systems.

Conclusion

In summary, ferrule fittings are essential components in various fluid systems, providing a secure and leak-proof connection between pipes and tubes. Understanding what ferrule fittings are, their types, applications, and maintenance is vital for engineers, technicians, and anyone involved in fluid transport systems. At Techtubes.in, we are dedicated to providing high-quality ferrule fittings that meet the needs of our diverse clientele across various industries.

With the right information and products, businesses can enhance system efficiency and reliability, ensuring safety and performance in their operations. If you have any further questions about ferrule fittings or related products, feel free to reach out to us.

what is a ferrule fitting