X-Ray Shielding Lead Rubber Sheet: The Ultimate Guide for Businesses

In today's highly regulated and technology-driven world, the need for robust radiation shielding materials is more critical than ever. Industries relying on the use of x-ray technology must prioritize safety, not only for their employees but also for clients and the surrounding public. One of the best solutions available is the x-ray shielding lead rubber sheet. This article will delve into the significance, applications, and benefits of this exceptional material, providing a comprehensive guide for businesses.

What is an X-Ray Shielding Lead Rubber Sheet?

The x-ray shielding lead rubber sheet is a specialized product designed to offer effective protection against harmful radiation. Made from a blend of lead and high-quality rubber, this material provides excellent flexibility and durability, making it suitable for various applications where shielding from radiation is necessary.

Key Ingredients

The x-ray shielding lead rubber sheet typically consists of:

- Lead: The primary component that absorbs and attenuates x-ray radiation.

- Rubber: Provides pliability, making the sheet easier to install and handle while ensuring longevity.

Why is X-Ray Shielding Important?

Radiation exposure can lead to severe health issues. Consequently, industries that utilize x-ray technology must adhere to strict safety regulations to minimize risks. Shielding materials like lead rubber sheets act as a barrier to protect workers and customers from unnecessary exposure.

Health Risks Associated with Radiation

Chronic exposure to radiation can lead to serious health issues such as:

- Cancer

- Genetic mutations

- Skin damage

- Reproductive harm

Applications of X-Ray Shielding Lead Rubber Sheets

The versatility of x-ray shielding lead rubber sheets enables their use in various industries, including:

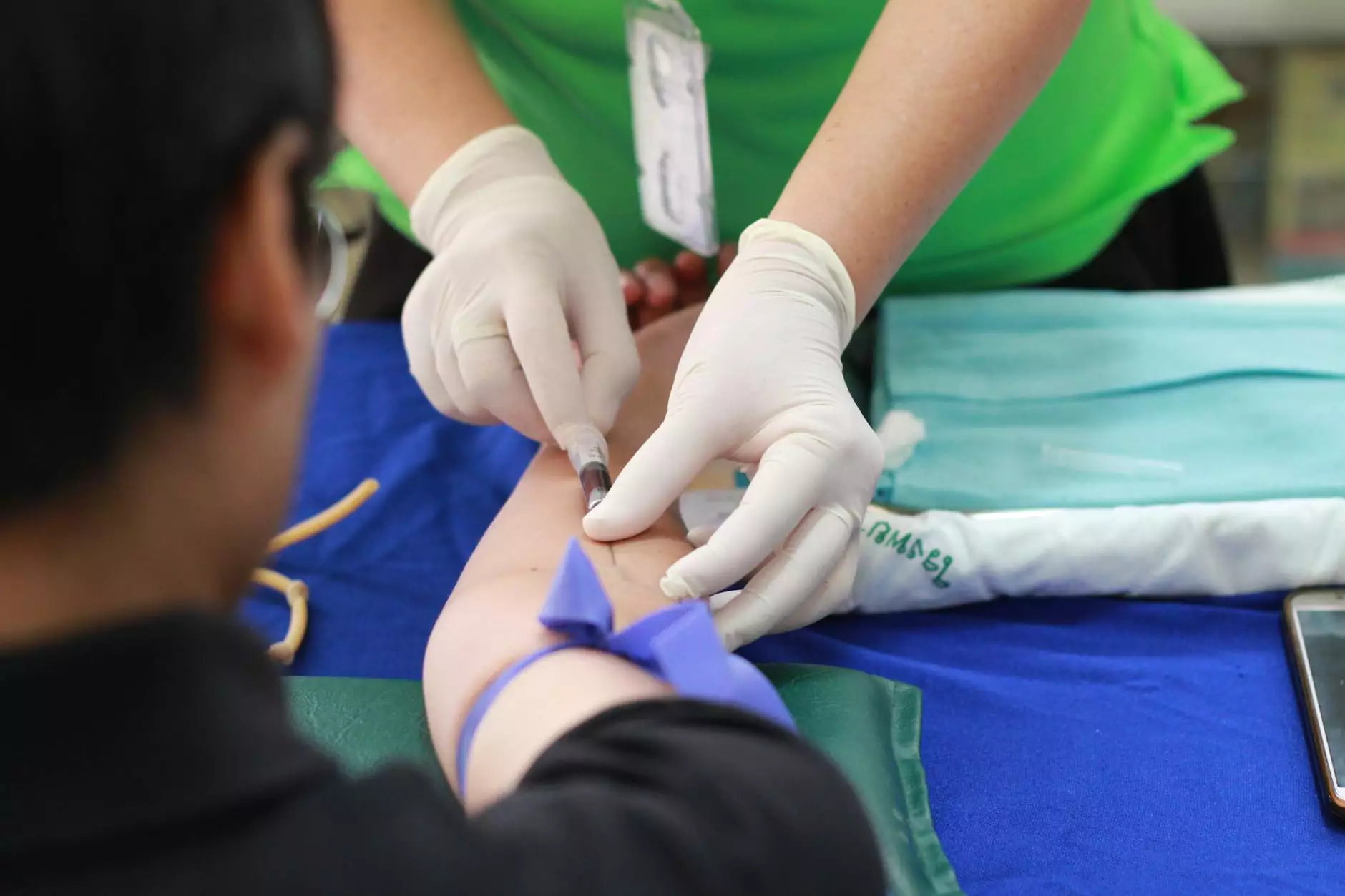

- Healthcare: Hospitals and clinics use these sheets in x-ray rooms, radiology departments, and CT scan facilities.

- Aerospace: Used in laboratories that conduct tests involving radiation.

- Academic Research: Necessary in universities where x-ray diffraction and other radiation-related experiments are conducted.

- Manufacturing: Industries that use x-ray inspection systems for quality control.

Benefits of Using X-Ray Shielding Lead Rubber Sheets

When it comes to radiation shielding, the x-ray shielding lead rubber sheet offers numerous advantages:

1. High Efficiency

Lead is known for its exceptional ability to absorb x-ray radiation, making it highly effective in protecting both personnel and patients.

2. Flexibility and Ease of Use

The rubber component allows for easy installation, cutting, and shaping, which is vital for constructing custom shielding solutions that fit specific spaces.

3. Durability

These sheets are resistant to wear and tear, ensuring a long lifespan even in high-traffic areas.

4. Lightweight

Compared to other radiation shielding materials, lead rubber sheets are relatively lightweight, making them easier to handle and install.

How to Choose the Right X-Ray Shielding Lead Rubber Sheet

Selecting the appropriate x-ray shielding lead rubber sheet requires careful consideration. Here are essential factors to keep in mind:

1. Thickness

The thickness of the lead rubber sheet is a critical factor. Depending on the application, the thickness should align with the level of radiation exposure anticipated. Consult industry standards and a professional to determine the required thickness for your specific application.

2. Lead Content

Different sheets may have varying percentages of lead. Higher lead content typically results in better protective capabilities against radiation.

3. Size and Shape

Custom dimensions may be necessary to fit specific locations or equipment. Ensure the supplier can accommodate your needs accurately.

4. Regulatory Compliance

Make sure that the shielding materials meet local and international safety regulations to ensure complete safety and legal compliance.

Installation of X-Ray Shielding Lead Rubber Sheets

Installing x-ray shielding lead rubber sheets requires attention to detail to ensure optimal effectiveness. Here is a basic guide to installation:

1. Preparation

Before installation, ensure that the surface where the sheets will be installed is smooth, clean, and free from any contaminants that may hinder adherence.

2. Measurement and Cutting

Measure the needed dimensions and use a sharp utility knife to cut the sheets accurately.

3. Adhesive Applications

Choose a heavy-duty adhesive designed for lead rubber applications for optimal bonding. Apply it evenly to the back of the sheet.

4. Positioning

Carefully position the sheet onto the prepared surface and press firmly to remove any air bubbles. Ensure a seamless fit for maximum protection.

5. Finishing Touches

Inspect the installation for any gaps or imperfections. If needed, use additional rubber trim or sealant to ensure complete coverage and efficacy.

Maintenance of X-Ray Shielding Lead Rubber Sheets

Proper maintenance will extend the life of your shielding materials. Here are some tips:

1. Regular Inspections

Conduct periodic checks for any signs of damage or wear. This proactive approach ensures that prompt repairs or replacements can be made.

2. Cleaning

Keep the surfaces clean using non-abrasive cleaners that will not damage the rubber or lead components. This will help maintain both hygiene and shielding effectiveness.

3. Avoid Direct Exposure

Minimize prolonged exposure to sunlight or extreme temperatures to prevent degradation of materials over time.

Conclusion: Invest in Safety with X-Ray Shielding Lead Rubber Sheets

For businesses in industries that utilize x-ray technology, investing in x-ray shielding lead rubber sheets is a crucial step in ensuring safety and compliance. By understanding the benefits, applications, and proper maintenance of these sheets, companies can protect their staff, customers, and ultimately enhance their reputation in the market.

At ovmdevice.com, we offer a wide range of radiation shielding materials, including high-quality x-ray shielding lead rubber sheets that meet stringent industry standards. Explore our products to find the perfect solution for your business's radiation protection needs.

By prioritizing radiation safety, you not only comply with regulations but also create a healthier work environment. Choose wisely, invest in quality shielding solutions, and ensure your operations run safely and efficiently.